Engine and turbine control for groundbreaking UAVs

The future of flight is with electric propulsion and we’re proud to be making huge leaps in innovative design for this sector. Mage Control Systems is currently designing a bespoke solution that does not currently exist, requested by a company seeking to revolutionise the future of UAV flight.

As UAV development continues to soar within industrial and consumer markets, the demand for increased capability will follow. Mage Control Systems stands at the forefront in this growing sector with our range of in-house technologies, expertise and unique design services.

Mage Control Systems was chosen as a design partner by our aerospace client to work alongside our senior engineers with their extensive experience in aerospace and defence sectors. Our engineering expertise is also drawn from safety-critical firmware development, advanced algorithm creation and mathematical modelling, setting the company apart from most other design SMEs.

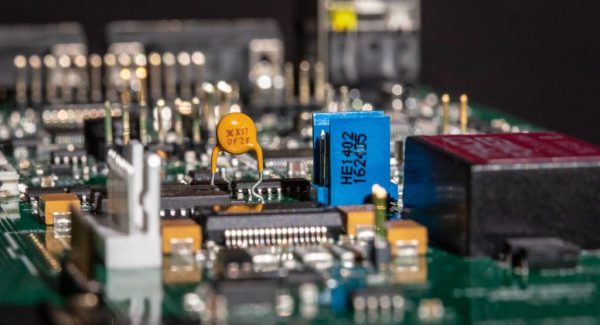

We are responsible for the design of both the Full Authority Digital Engine Control (FADEC) and Power Management Unit (PMU). The FADEC essentially serves as the engine control unit for the UAV and monitors various parameters in order to achieve optimal performance. The PMU serves to control the electrical power BUS system.

The design team at Mage Control Systems has consolidated a number of separate PCBs onto only two units by means of a stacked PCB assembly. The tightly coupled FADEC and PMU allow for the fast, dynamic rate of change of engine control and power balancing functions under variable load conditions. Our unrivalled high-power density designs are perfectly suited to meet the project requirements for a complex battery/generator solution.

Our key expertise is both in high-power electronics and motion control for hardware design; essentially, this is achieved via the development of complex control laws and algorithms using state of the art tools such as MATLAB, Simulink and associated toolchains. Development using these tools allows for fault-free automatic code generation to meet DO-178C standard.

The PMU and the FADEC systems utilise a very fast processor loop cycle period for efficient space-vector modulated sinusoidal commutation – the electronics are rated up to 200,000RPM. The system is also fully dual-redundant (from processor to bridge to motor feedback) and the electronics have been designed to meet the required DO-254 standard. The hardware is also designed to meet DO-160G standard.

We are keen to grow our network in this evolving sector and would welcome any enquiries from those looking to develop similar products. Please get in touch at [email protected].